Hybrid Refrigerator Using Outdoor Air

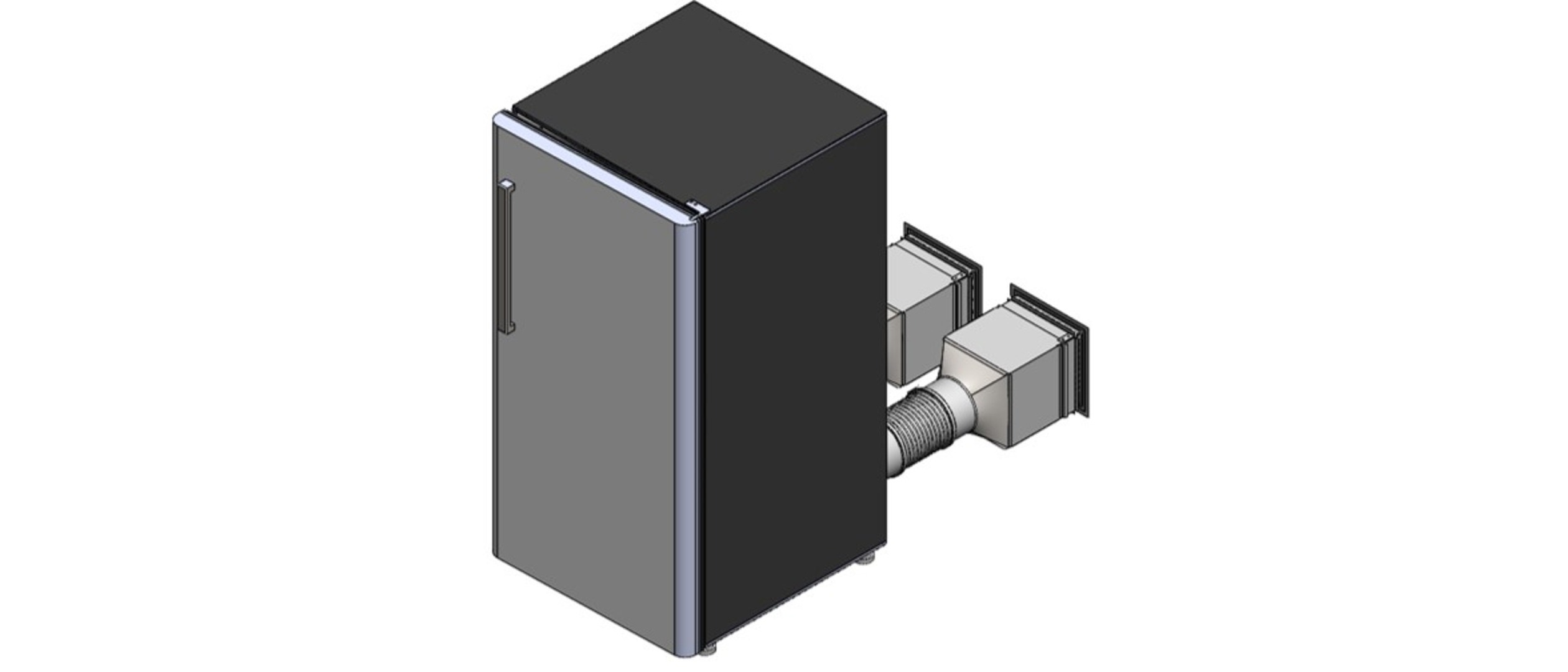

Capstone concept: exploit Canadian winter for “free cooling”, and reject heat outdoors in summer to avoid heating the home.

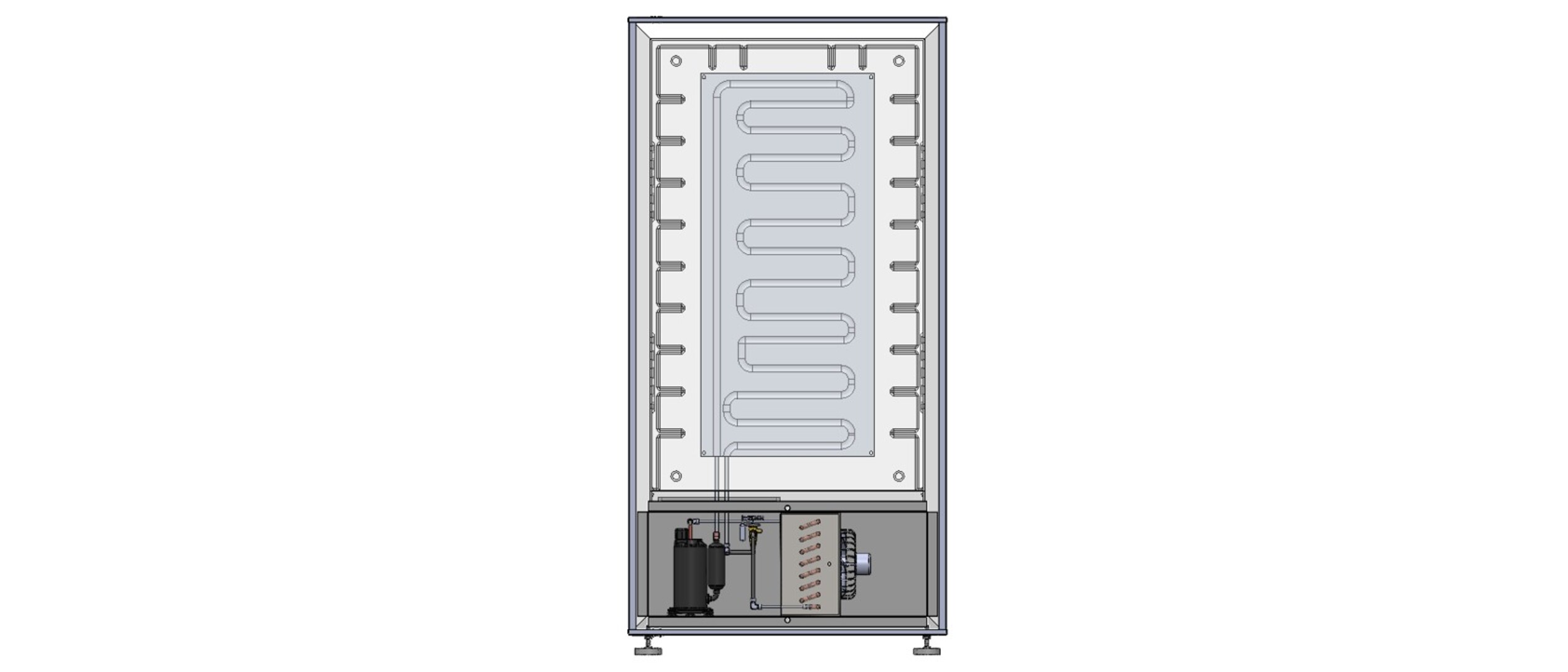

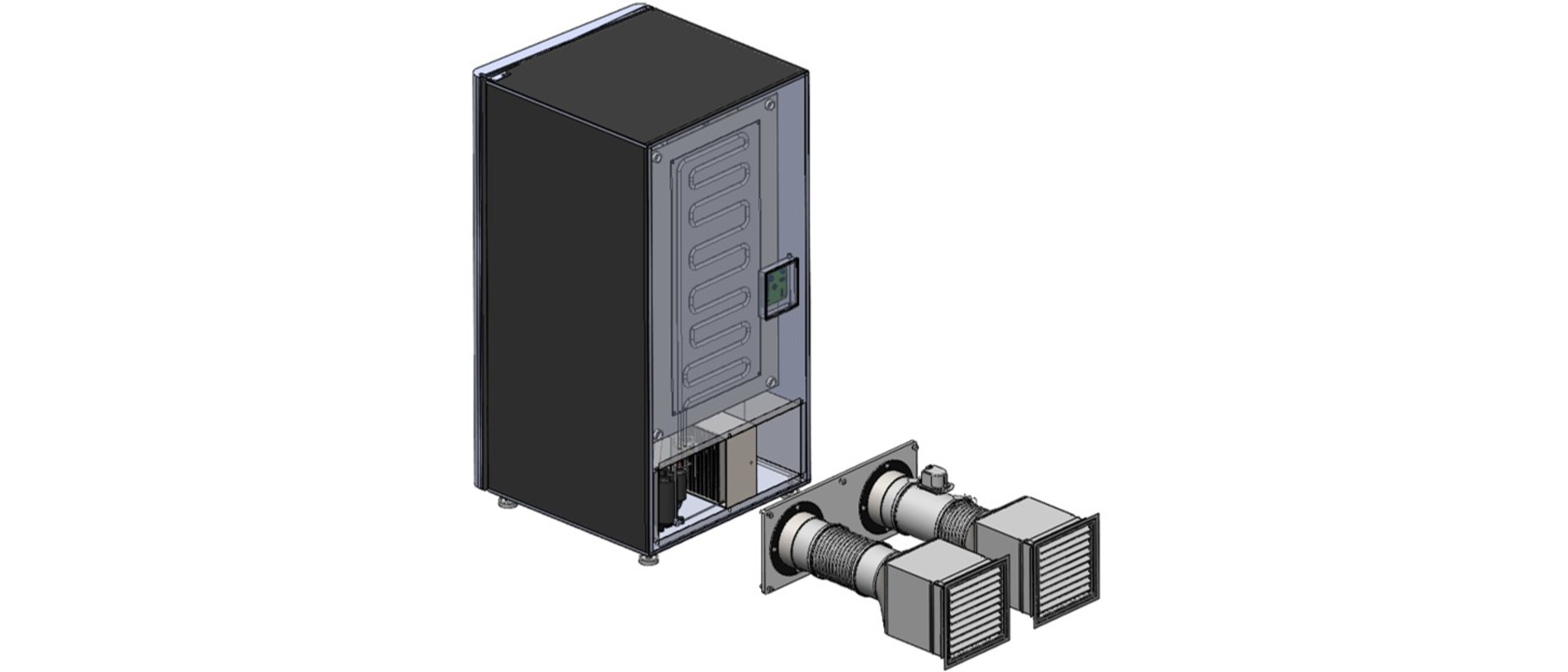

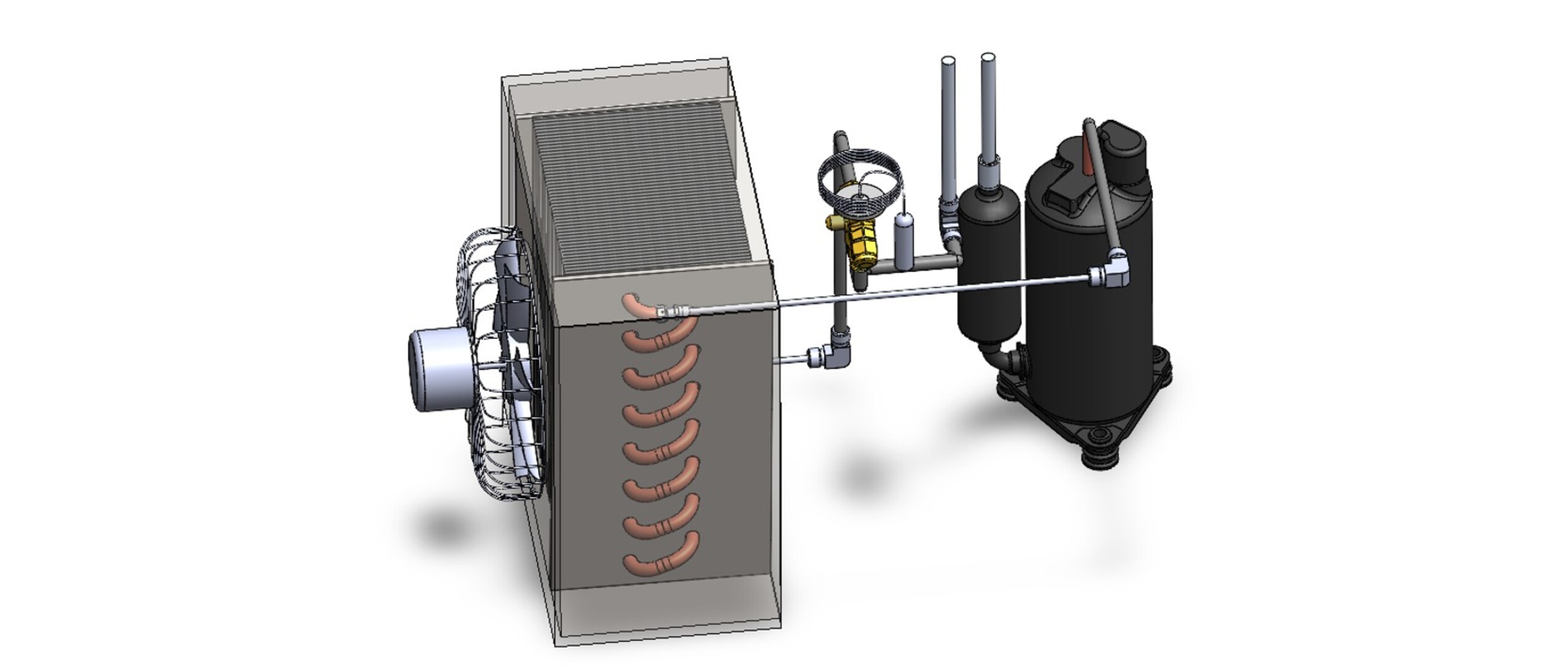

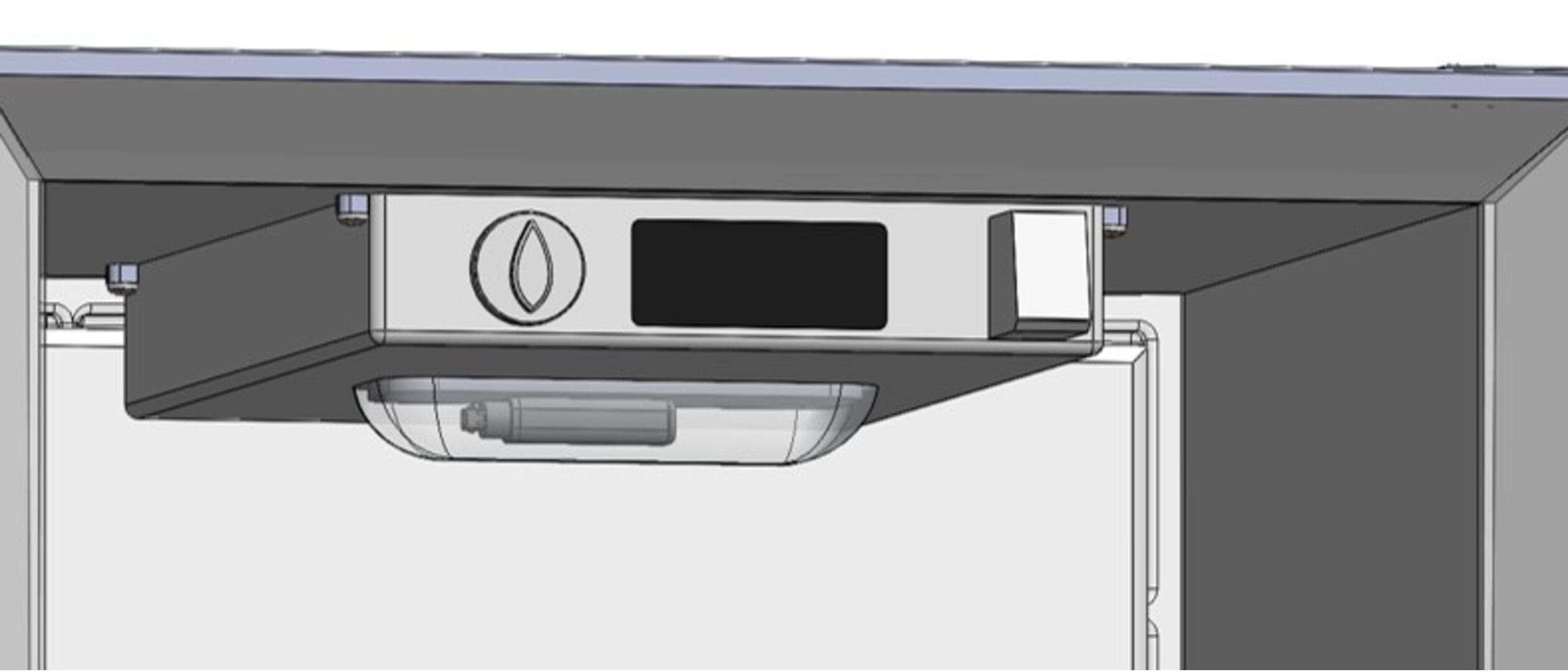

The condenser–compressor is isolated in a sealed compartment and selectively vented outdoors, improving heat rejection in winter and preventing indoor heat gain in summer.

1/7 — Outdoor-air hybrid concept

/ Challenge

Reduce the fridge’s energy consumption while preventing indoor heat gain and keep the system autonomous, safe, and easy to install/remove.

/ Solution

Create an insulated condenser compartment connected to outdoors by two short insulated ducts (intake/exhaust), use a motorized damper + temperature/humidity logic to switch between winter “free cooling” and summer operation, and model the full loads + vapor-compression cycle with R600a.

/ Results

Quantified a full cooling load model (Q̇load ≈ 335 W) and demonstrated a dramatic winter-side performance lift (modeled COPwinter ≈ 229 vs COPsummer ≈ 4.08) driven by improved condenser heat rejection using outdoor air.

> Workflow: model-driven concept + practical install constraints

Cooling load model

Vapor-compression cycle

Air + ducting system

Autonomous operation

- MANDATE

- Use outdoor conditions to reduce compressor workload (winter) and reject heat outdoors (summer) to avoid heating the home.

- REQUIREMENTS

- Maintain ≤ 4°C • cost-effective • durable/corrosion-resistant • easy install/remove • reliable user-independent control.

- REFERENCE FRIDGE

- French-door scale: W ≈ 0.91 m · D ≈ 0.86 m · H ≈ 1.78 m

- COOLING LOAD

- Q̇load ≈ 335 W (walls + infiltration + product load)

- REFRIGERANT

- R600a (low-GWP), domestic-scale compatible

- MODELED COP

- COPsummer ≈ 4.084 · COPwinter ≈ 229 (free-cooling effect)

- COMPRESSOR WORK

- Ẇcomp,summer ≈ 82.1 W · Ẇcomp,winter ≈ 1.5 W

- AIR SYSTEM

- Insulated condenser box + two short insulated ducts (intake/exhaust), motorized dampers, hood vent + backdraft protection.