Brake Disc Topology Optimization

Lightweight Formula Student rotor redesigned using topology + FEA validation.

Built a baseline brake disc, ran topology optimization to remove non-critical material, redesigned a manufacturable geometry, then validated it in ANSYS using static structural (Von Mises / deformation) and transient thermal analysis to predict temperature rise during braking events.

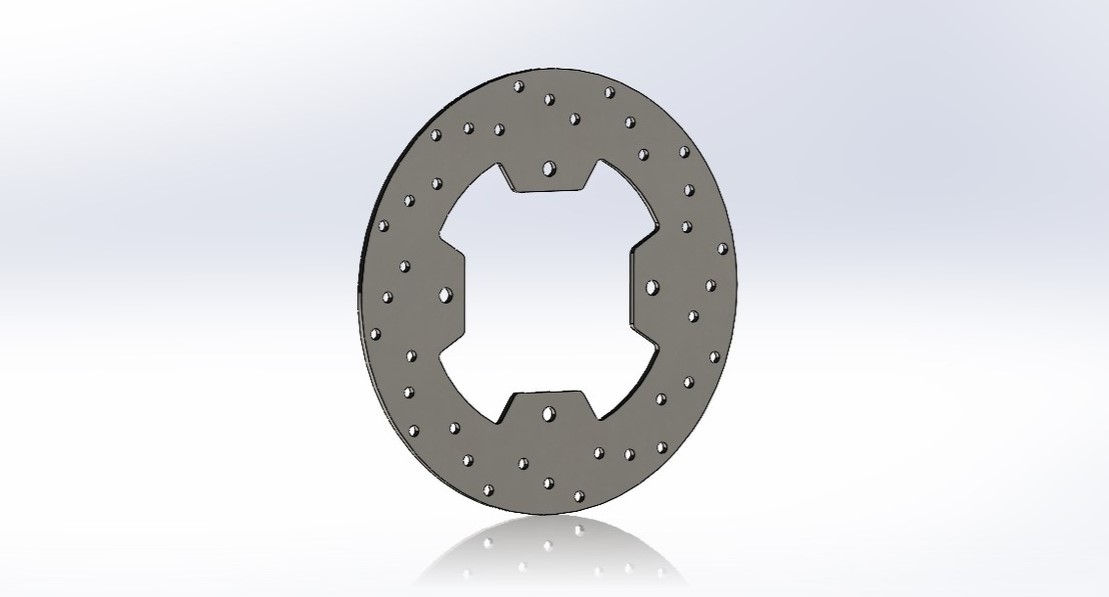

1/7 — Geometry-driven design

/ Challenge

Reduce unsprung mass while ensuring stiffness and safe stresses under braking torque and heat.

/ Solution

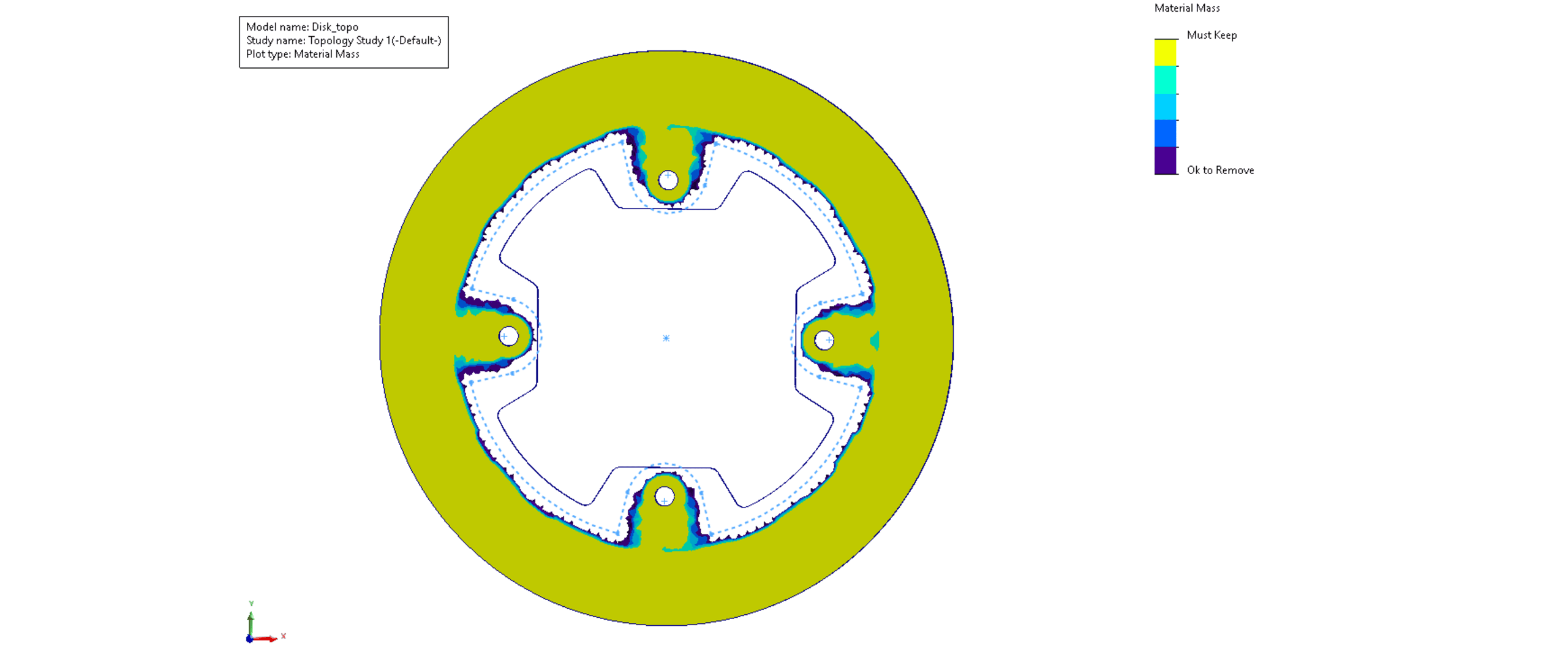

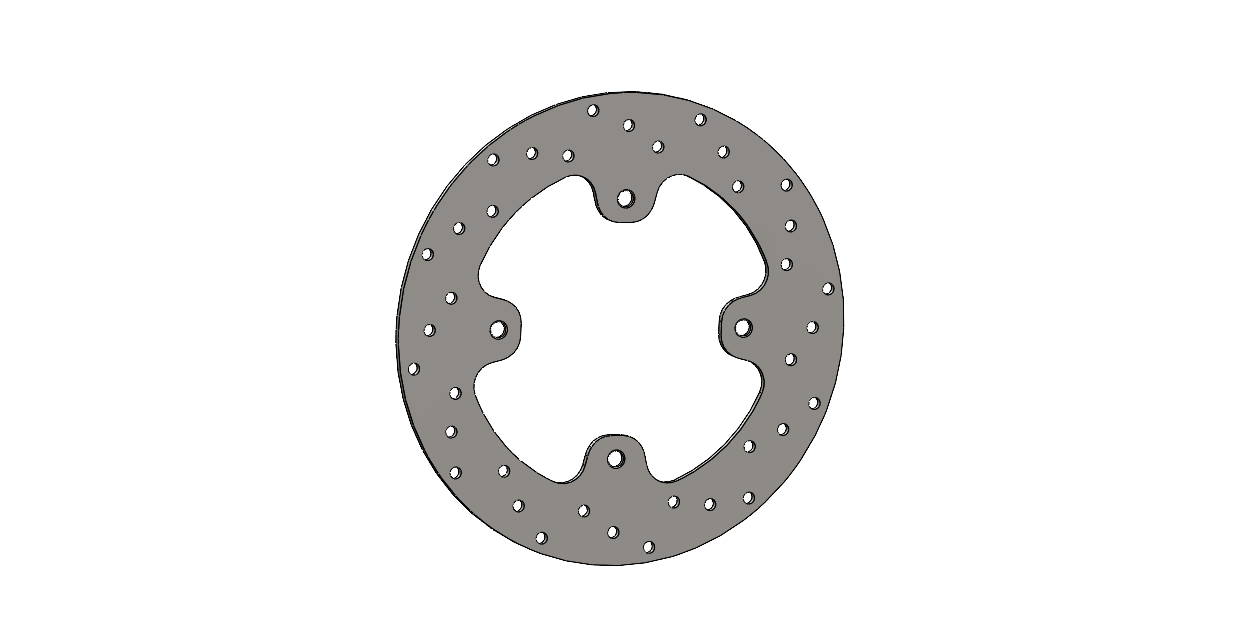

Built a baseline rotor CAD, ran SolidWorks topology optimization to identify removable regions, then redesigned a manufacturable geometry and validated performance in ANSYS using static structural and transient thermal simulations.

/ Results

Delivered a lighter disc concept with controlled stress concentrations and limited deformation, plus quantified temperature rise & hotspots over time to support motorsport-oriented design decisions.

> Workflow guided by simulation-driven design

Topology optimization

Manufacturable redesign

Static structural (ANSYS)

Transient thermal (ANSYS)

- MASS REDUCTION

- ≈ 15 %

- ROTOR GEOMETRY

- OD 200 mm · ID 140 mm · thickness 3 mm

- STRUCTURAL CASE

- Hub constraints · Tangential braking load · Total Hydraulic Pressure

- PEAK VON MISES

- 79.9 MPa (localized)

- THERMAL CASE

- Transient heat flux at pad interface · Convection on exposed surfaces

- PEAK TEMPERATURE

- 468°C during braking event